A Closer Look at Bankfull Culvert Design

Have you ever noticed when driving or walking past a multiple box culvert under a road how one culvert opening is clear or empty and the others are partially or completely full of dirt? If the culvert is designed to convey water, then where does all that dirt come from?

If you are like me and the pondering sort, the next questions that come to mind are:

- If one open culvert is all that was needed to convey enough water to keep the road from washing away, then why did they spend the money on installing all of the others?

- If one culvert is not sufficient, then where will all that water (and possibly the road itself) go when the next big flood comes and all that water cannot make it through the one opening fast enough?

The truth is all those culverts and their capacities were necessary; in fact, many flooding problems and road washouts are the result of partially or completely occluded culverts.

So how do we keep this from happening? Do we send out crews on a regular basis to clean out the culverts?

In many cases this is exactly how it is handled, but this is a very expensive solution to the problem. Because of the expense and the number of culverts to be cleaned, culverts can be missed, leading to catastrophic consequences. Unfortunately, this is a problem that humans have been coping with since the time of the Roman Empire, and many civil engineers will tell you this is just an unfortunate fact of life and bridges.

But what if I told you there was a way to design culverts where construction costs would stay the same, and you would never have to clean the culverts ever again?

Good news: It can be done! And the answer to your next question, “Well, why didn’t we figure it out sooner?” has an interesting answer.

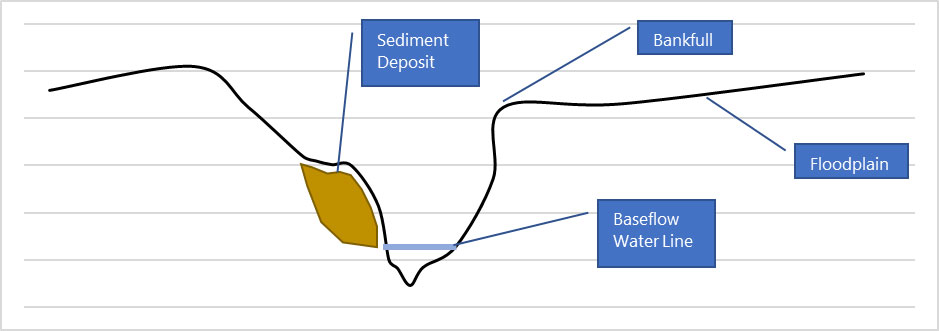

Historically, civil engineers have looked at streams as open pipes that convey water, but that isn’t exactly correct. When biologists and engineers collaborated to work on channel designs for river restoration, they needed to first quantify and describe what a natural river looks like and how it changes between low flow conditions and flood stage. What they found was that river channels in cross-section tend to have this general shape:

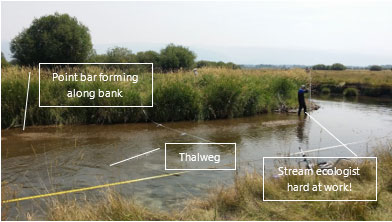

The shape of the channel, the “pipe,” looks quite different than the square or rectangle box shapes of the culverts you are likely familiar with. Under clear skies and normal conditions, the water in the stream flows in the lowest part of the valley (where you see the baseflow water line above). All streams carry some amount of sediment, and the force from this baseflow is sufficient to keep that sediment suspended and moving. As a result, a healthy natural channel is free of excess sediment along its bottom (or thalweg as the technical people call it).

As it begins to rain in the watershed and the water in the channel begins to rise, the increased energy from the floodwaters pick up sediment from within the channel as well as convey sediment that has washed down from the surrounding hill slopes. The waters will continue to rise, carrying more and more sediment until they reach the bankfull elevation.

When the water level reaches the bankfull elevation, water escapes out onto the floodplain. On the floodplain, the waters are no longer confined (i.e. they are no longer in a pipe, but rather spilling out and spreading across the floor like spilled milk) and their energy dissipates. Think about it like putting your thumb over the opening of a flowing garden hose, then taking it away. The water has less force when you move your thumb.

Because the water has less force, it no longer has enough energy to keep the dirt and sediment it picked up on its trip down valley suspended in the water. As a result, the sediment is deposited on the floodplain. This mechanism of flooding and sediment deposition is why the Mississippi floodplain is such fantastic farmland.

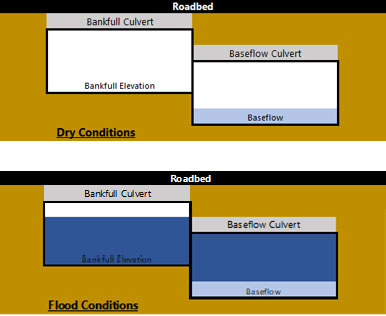

Now, let’s consider what happened in the box culverts above. As the floodwaters begin to recede, they will begin to deposit sediment as they lose energy. Whichever culvert is more directly in line with the thalweg of the approaching channel will remain clear as baseflow will travel through this culvert, keeping it clean and swept free of sediment. This is where the swiftest water flows during the flood and is the last to slow down.

The adjacent culverts act as the floodplain. The waters slow down and recede from these culverts first, so these begin to fill with dirt and debris. With each successive flood, more sediment is deposited, the blocked water is diverted to the other culvert with greater and greater force each time, and eventually the force becomes so great that the culvert fails.

So what is the solution? Staggered culverts!

If one culvert is placed at the elevation of the thalweg, and the other culvert is placed at the elevation of bankfull, then the floodwaters in either culvert will always have enough force to keep the sediment suspended and moving, thereby naturally keeping the culverts clean. The bankfull culvert only has water in it at the time of flood when it is needed. As the waters recede below this elevation, they still have enough force to keep sediment suspended as they transition to the lower baseflow culvert. Once confined to the baseflow culvert, sufficient velocities will continue even during low flow conditions to keep the culvert clear of sediment and debris.

Just imagine the savings to transportation departments if they no longer have to pay for the equipment and labor required to clean the millions of culverts across the country. These tax dollars could then be used toward building new roads to growing communities or repairing the nation’s aging infrastructure.

Now for the disclaimers, and you knew they were coming. Each stream channel is as different as every person is. A detailed geomorphological survey should be conducted to determine the appropriate placement of structures, the number and size of structures required, and the shear stresses involved. Changes in boundary conditions (e.g. increases in impervious surface in the watershed, changes in discharge frequency and volume, etc.) may change the overall efficacy of the final design over time.

Many states and municipalities have already started requiring this type of design for culverts, but until standard plans are developed and approved for your region by your local transportation regulatory agency, a stream channel design expert should be consulted during design of structures and placement.

When planning your next road project with stream crossings, I hope you will consider this approach as a cost effective solution for your clients. RS&H has a full complement of road and bridge design engineers, transportation construction management engineers, and stream restoration designers, and we would be happy to help!